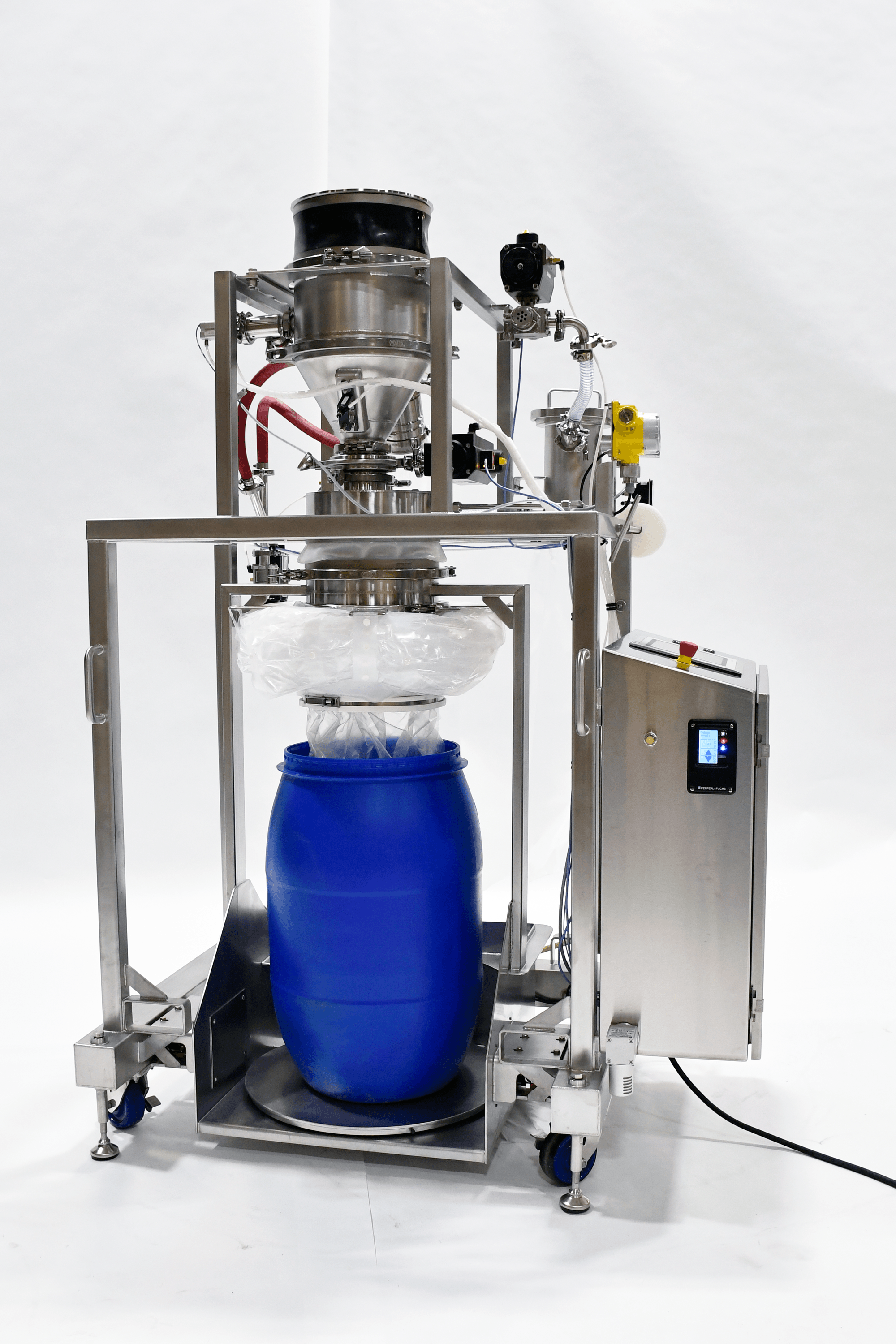

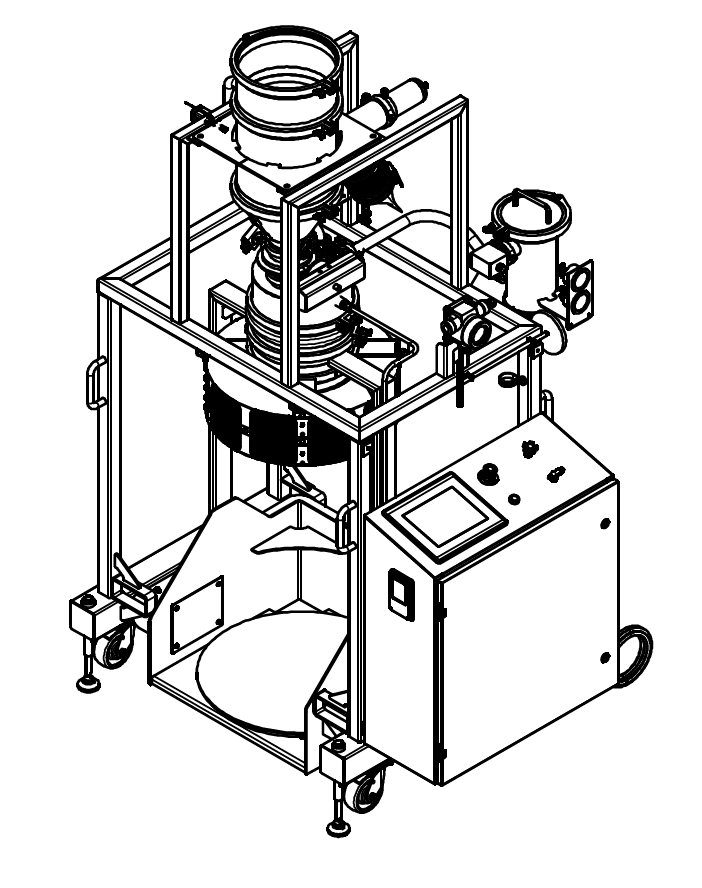

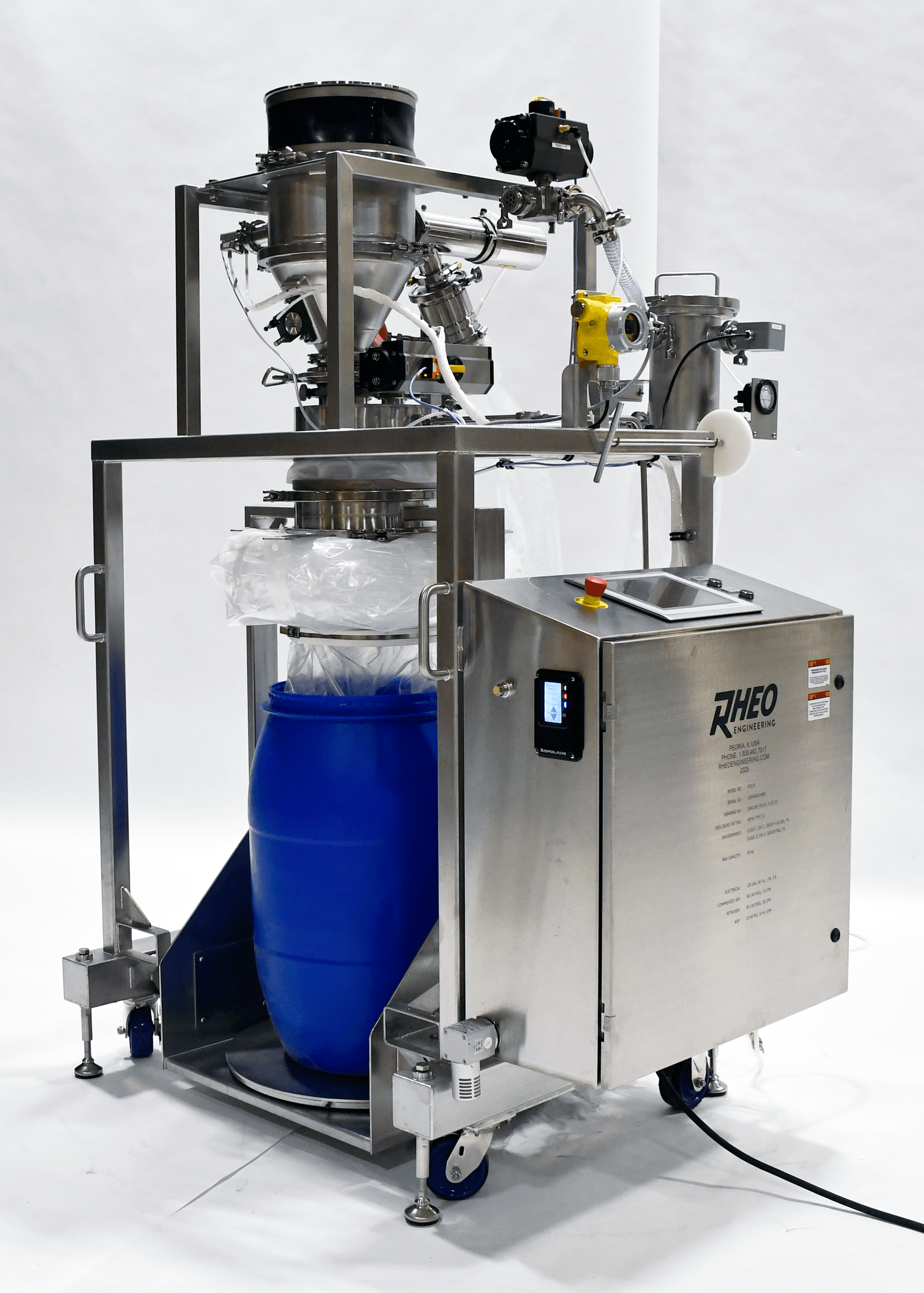

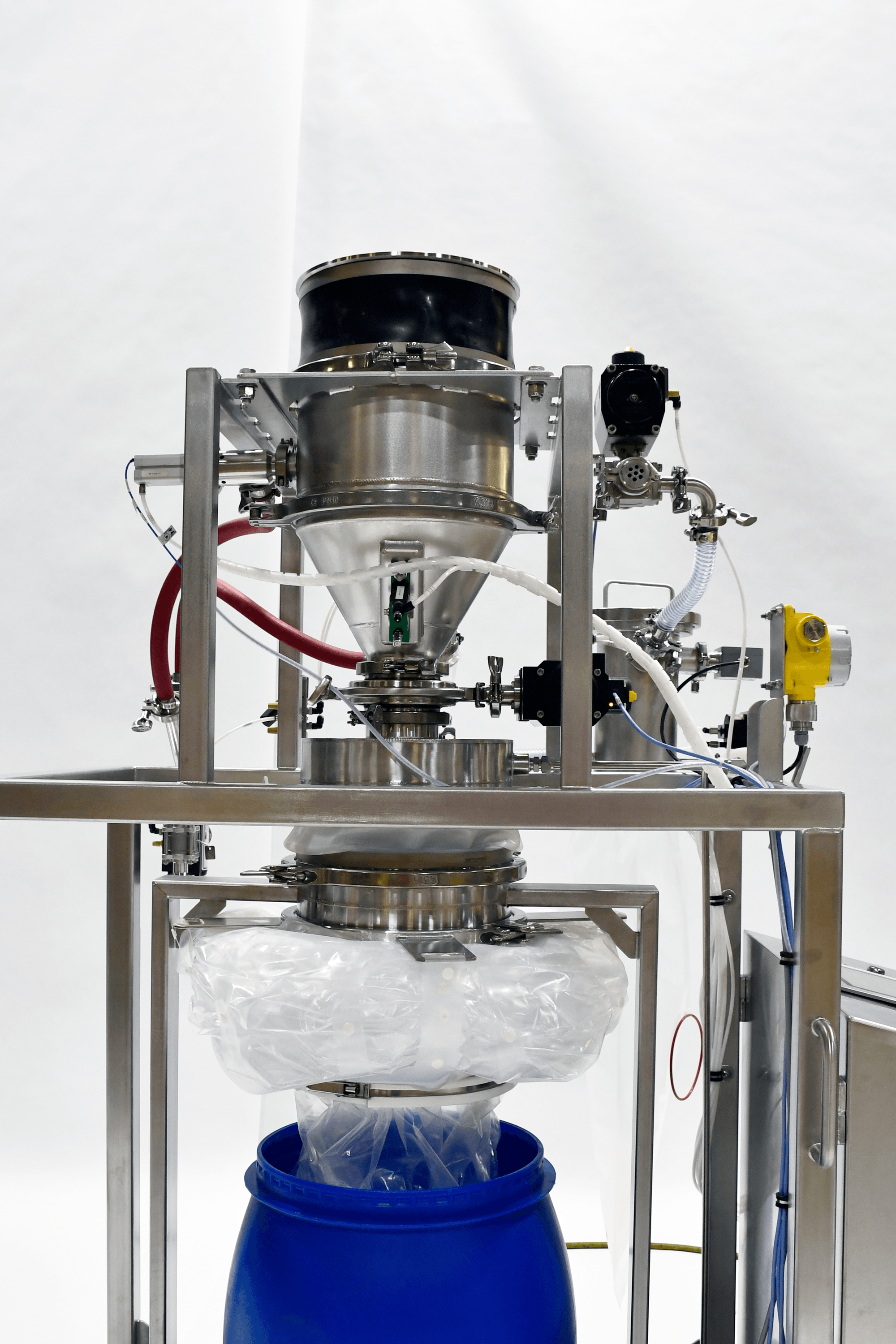

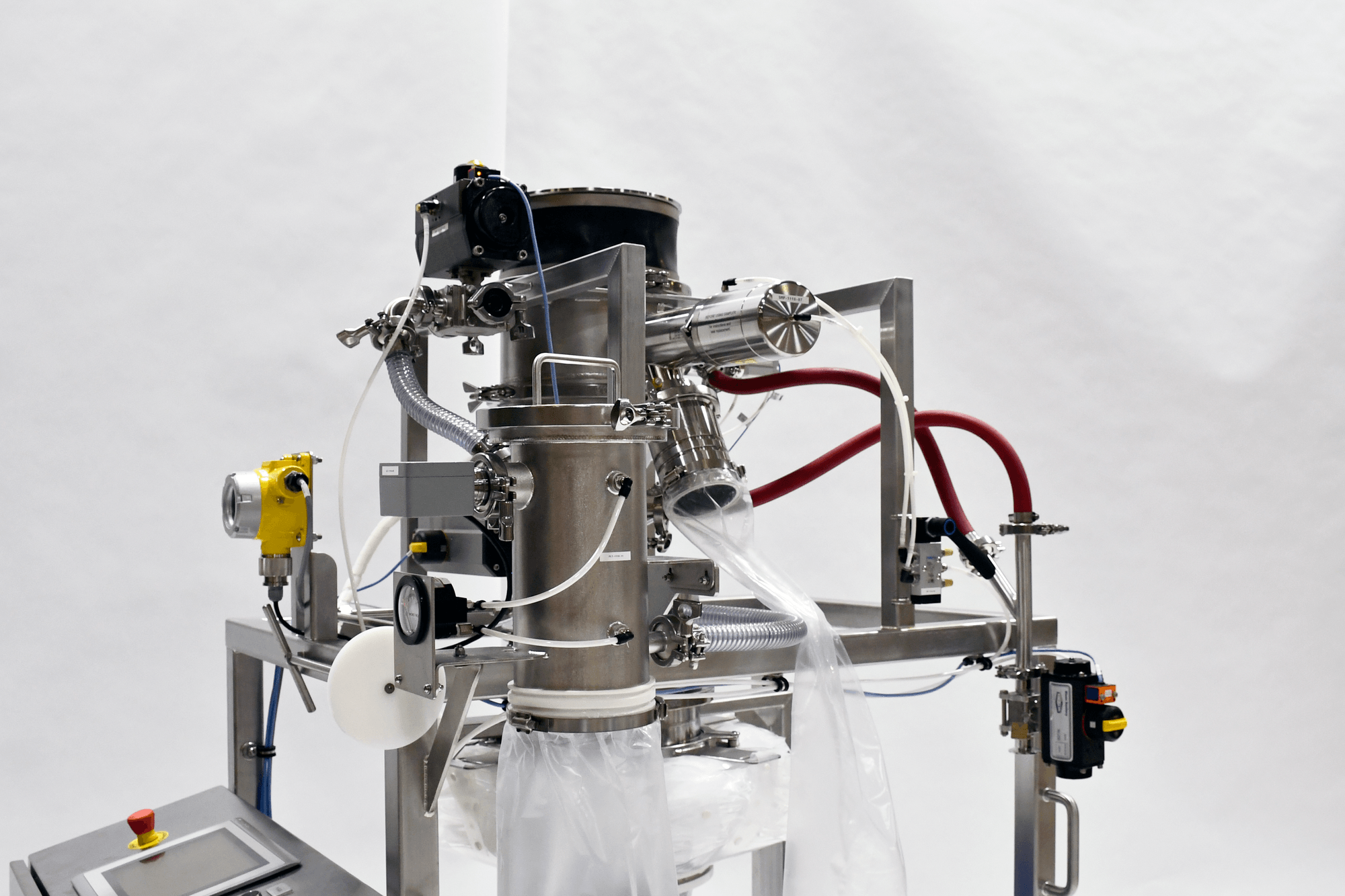

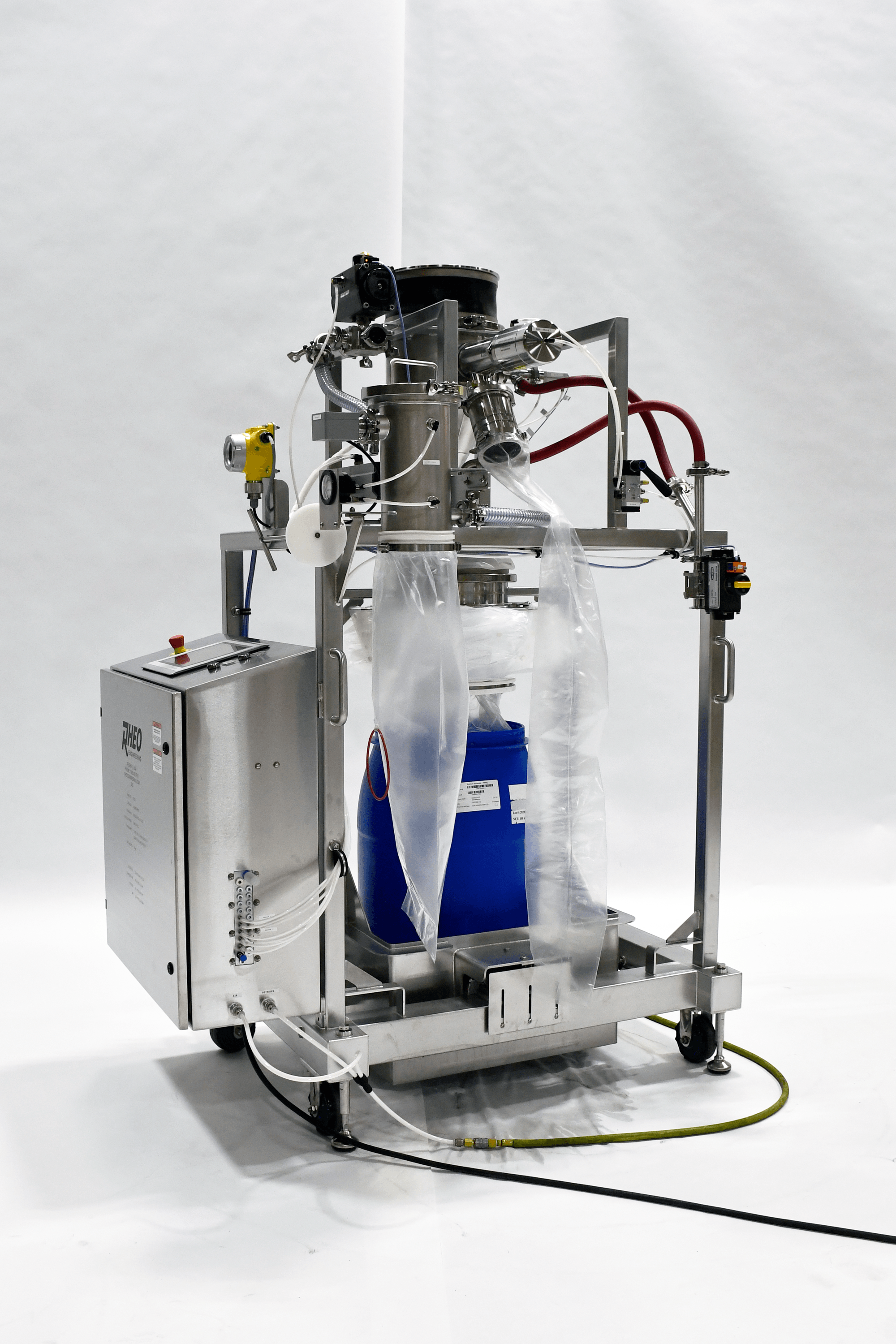

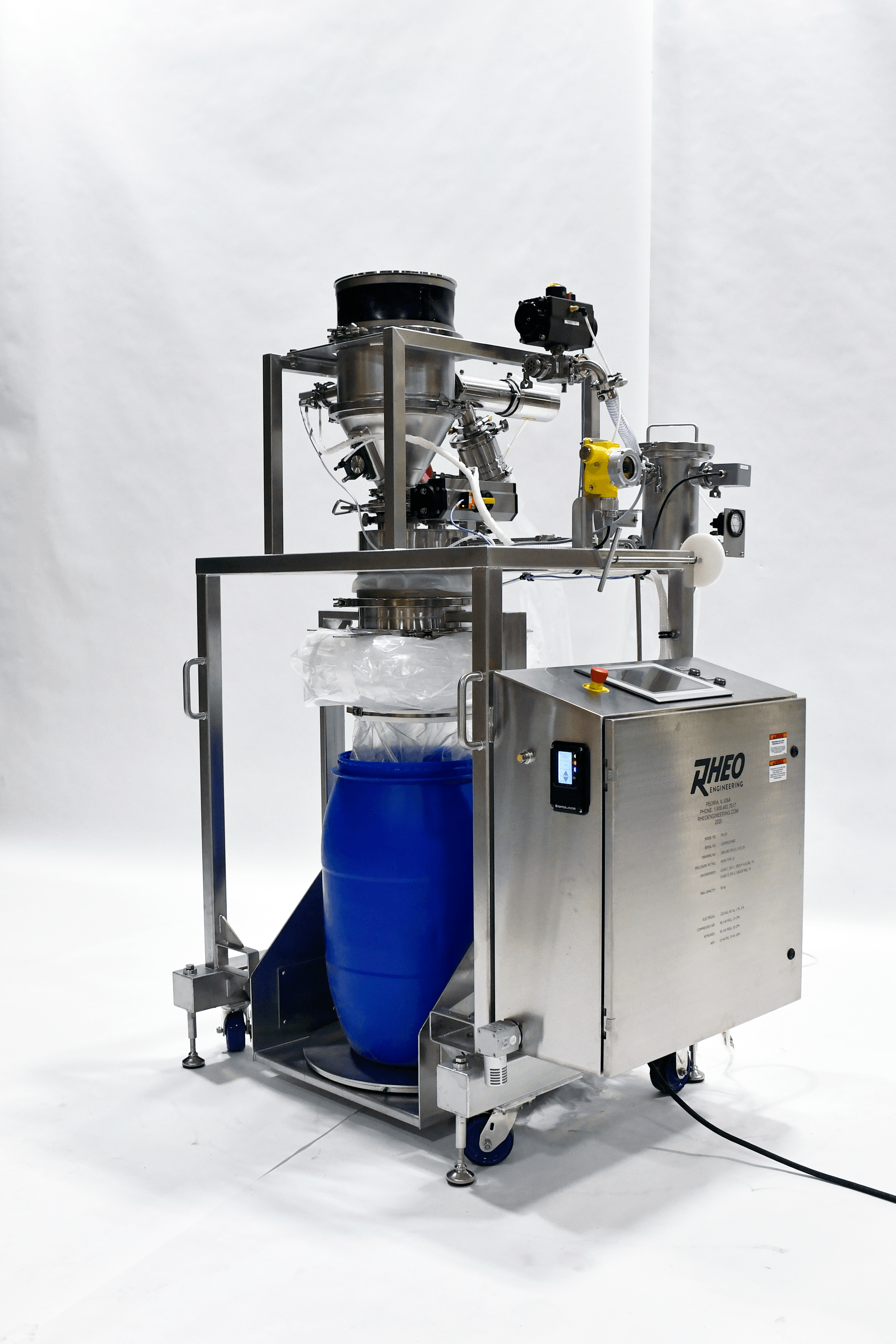

For this project, Rheo provided an Automated Packout Station for filling drums within an API manufacturing facility. It was designed for use in a Class I & II, Division 2 area, where a discharge vessel was attached to an anti-static flexible compensator on top of the station. Prior to dosing, the unit featured the capability to purge the system with nitrogen while being able to monitor the oxygen percent levels. The pneumatic rotary valve precisely filled the receiving drum liner with material while the pneumatic vibrator allowed for consistent flow. Throughout dosing, there was a pneumatic manual sampler that was lined with the Rheo Flexibles Continuous Liner system. The final pack-out was completed by also using the Rheo Flexibles Continuous Liner system and RheoFlex 302 film.

The weighing system utilized load cells that communicated with the PLC for accurate material dosing and the operator utilized the HMI touch screen for any operations. The WIP feature was completed by a 360 degree retractable spray device and Rheo Flexibles Tundish Cleanout system. The Packout Station was mounted on mobile casters for ease of motion and leveling feet for stability.