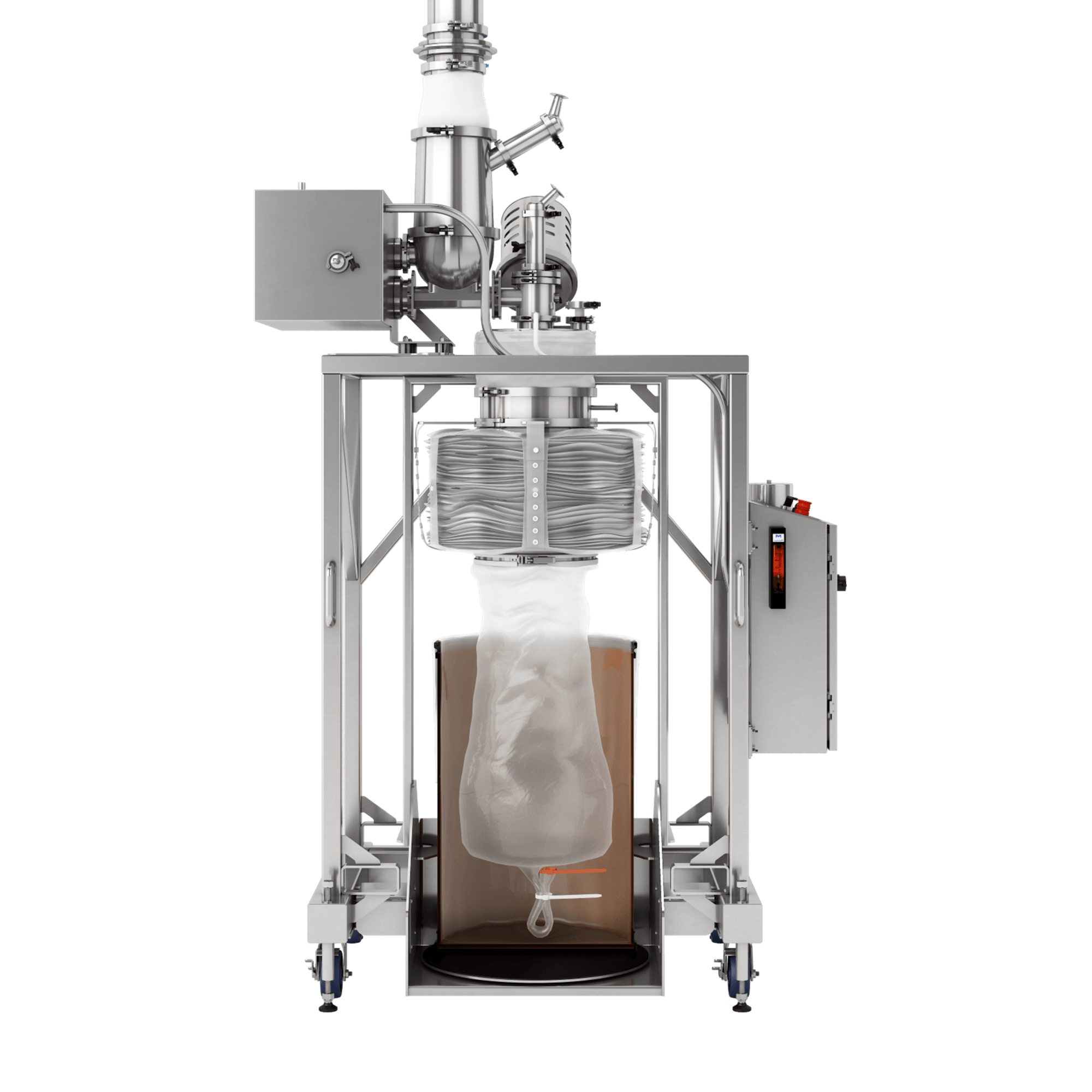

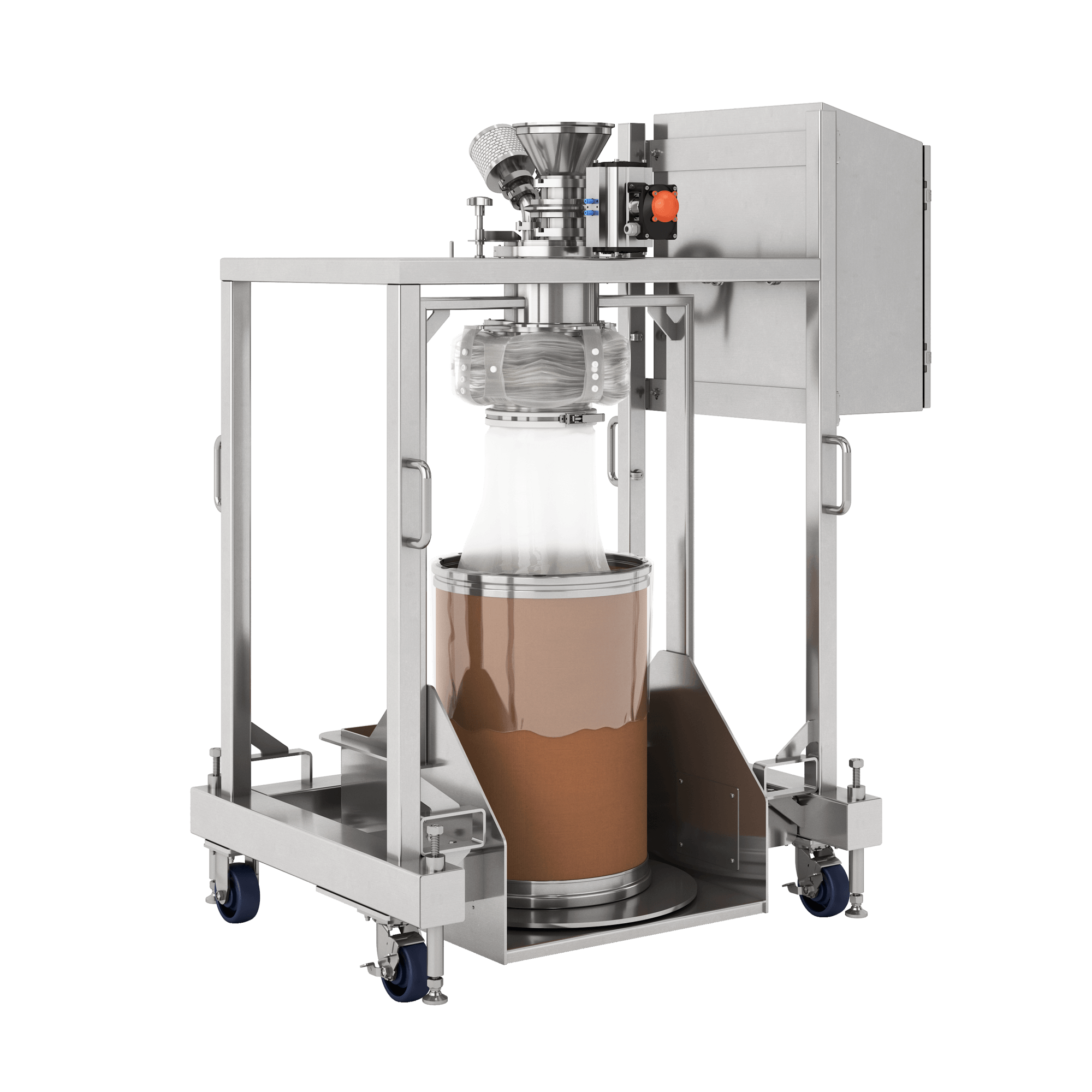

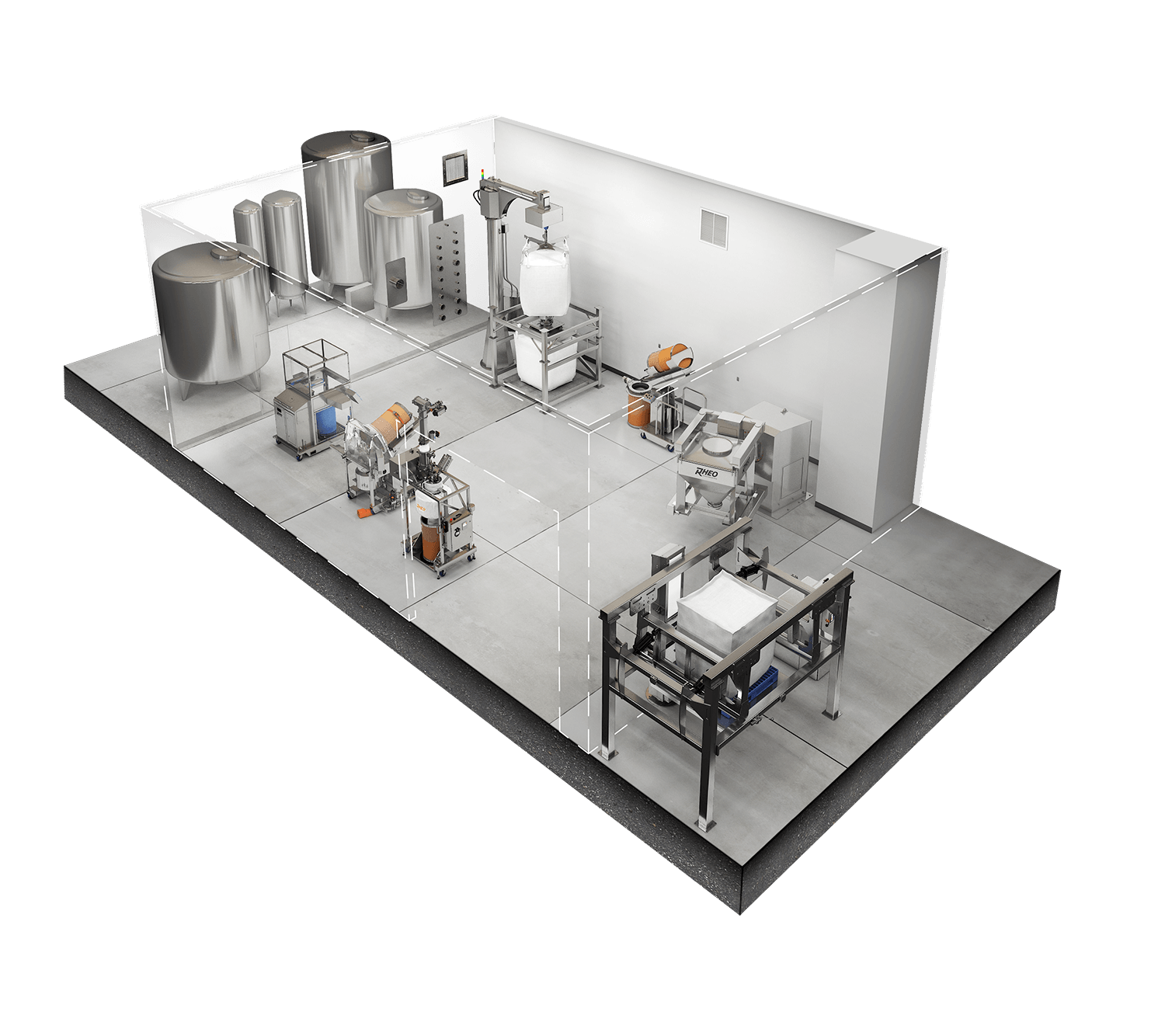

The Rheo Packout Station is designed to facilitate the efficient filling of drums to an accurate weight. After the target weight is achieved, the system automatically stops the material transfer and notifies the operator.

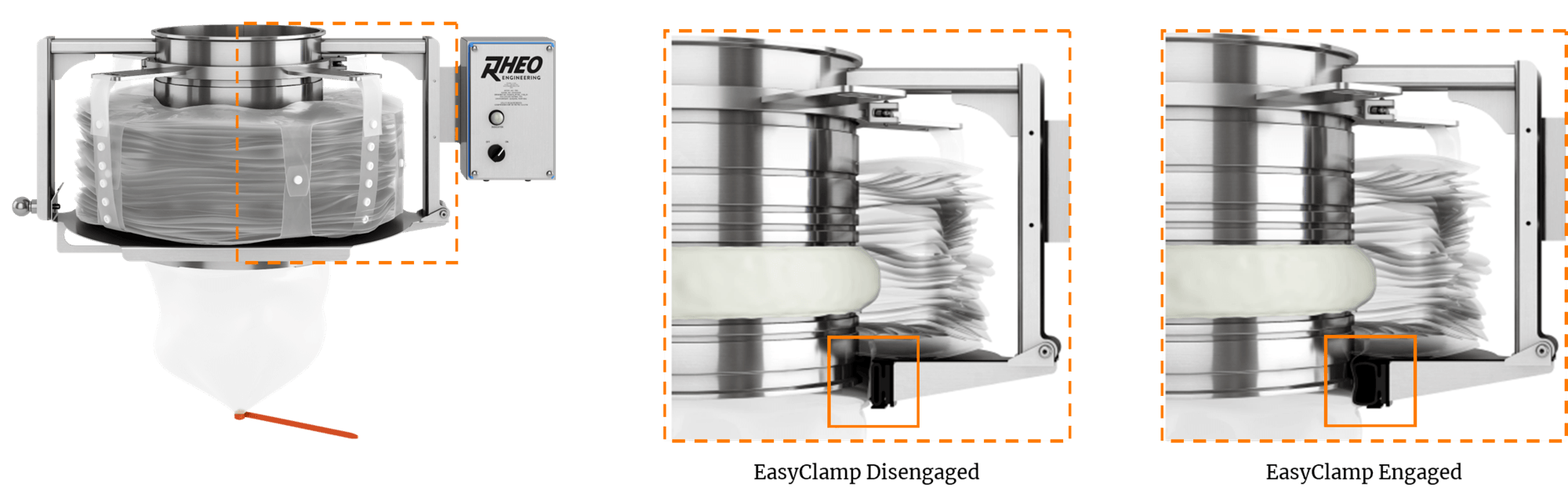

The Rheo Packout Station offers a high containment, continuous liner solution for safely packing off powder into drums.